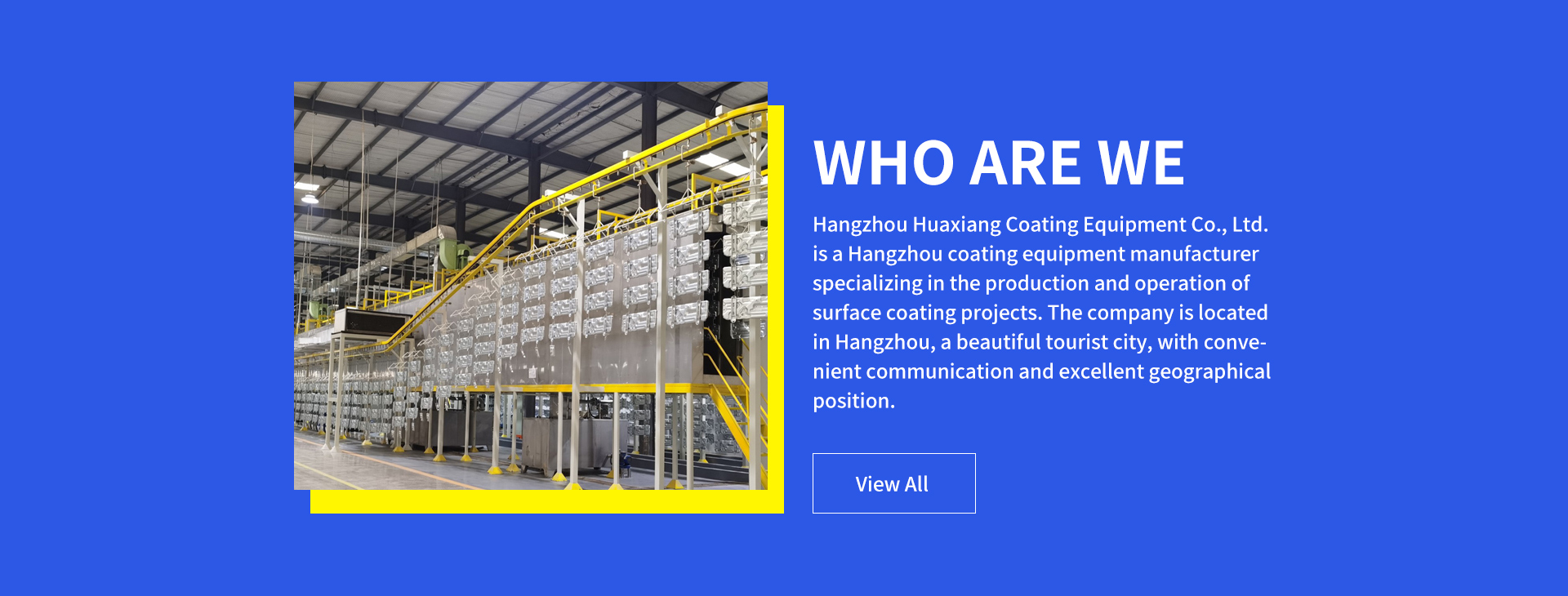

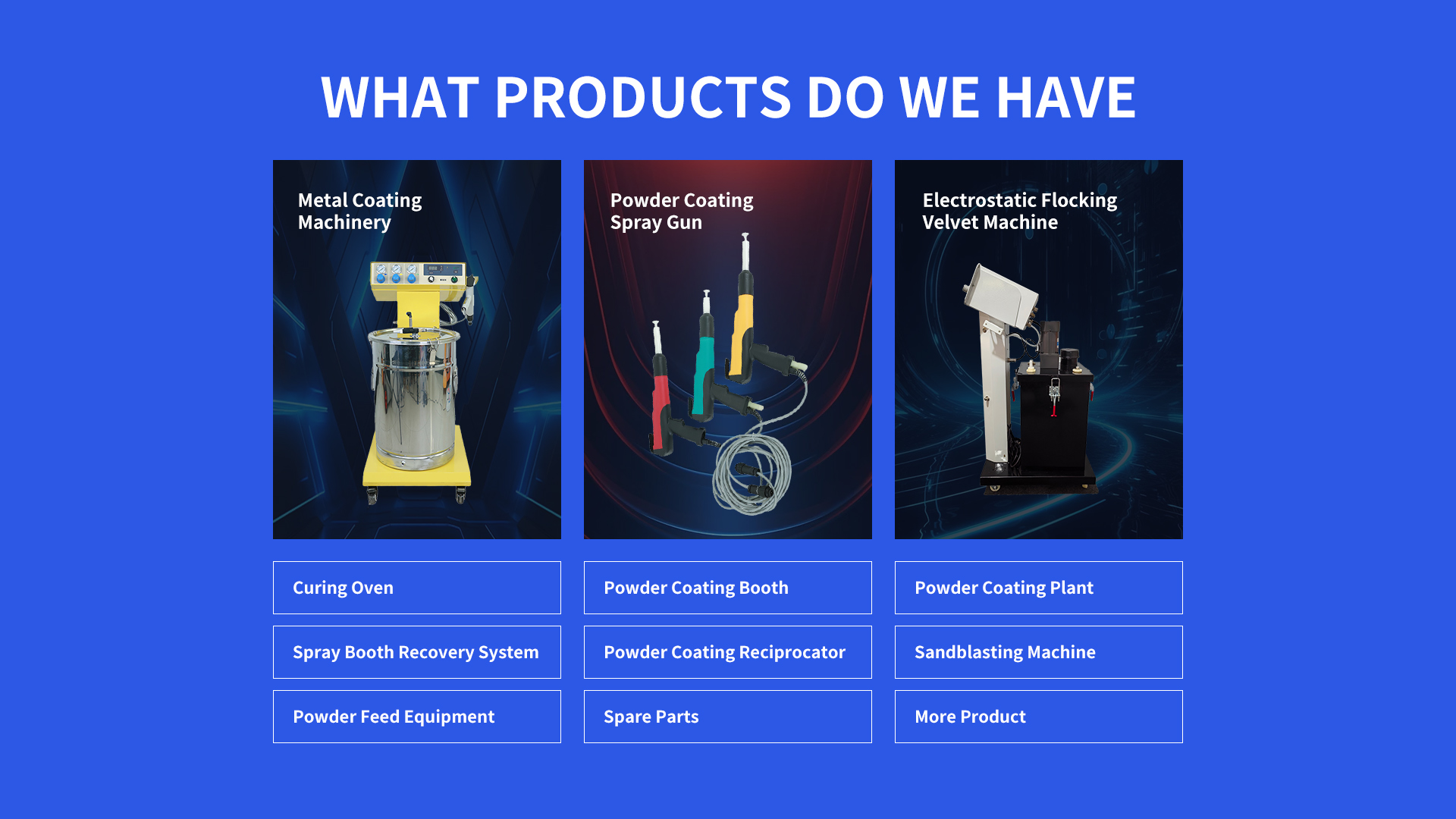

1. Powder Coating Equipment Package Factory Overview and Components

A Powder Coating Equipment Package Factory integrates specialized systems for end-to-end powder coating production. Core components include electrostatic spray guns, automated conveyor lines, pre-treatment stations (cleaning, phosphating), curing ovens, and powder recovery units. Factories often customize setups with robotic arms, IoT-enabled controls, and modular designs to optimize throughput and quality. These systems ensure precision coating for metals, plastics, and ceramics in industrial-scale operations.

2. Applications of Powder Coating Equipment Package Factory

These factories serve automotive manufacturers, aerospace suppliers, appliance producers, and architectural firms. They mass-coat car parts, aircraft components, household appliances, and building materials. Suitable for steel, aluminum, and heat-resistant plastics, they deliver uniform, durable finishes that resist corrosion, UV exposure, and wear.

3. Pricing of Powder Coating Equipment Package Factory

Full factory setups range from 200,000forsemi−automatedlinesto2 million+ for fully robotic systems. Costs depend on production capacity (e.g., 500–5,000 parts/day), energy efficiency, and customization. High-end brands like GEMA and Durr offer scalable solutions with advanced IoT integration and warranty support.

4. Proper Usage of Powder Coating Equipment Package Factory

Pre-treatment: Clean and pre-treat surfaces to remove contaminants.

Automated Coating: Program robots for precise spray patterns and voltage (30–100 kV).

Curing: Bake parts at 350–450°F for 10–30 minutes.

Recovery: Recycle 90%+ excess powder via cyclone filters.

Maintenance: Clean equipment daily and inspect ovens weekly.

5. How to Choose a Powder Coating Equipment Package Factory

Scale: Match factory capacity to projected demand (e.g., 1,000–10,000 units/month).

Automation: Prioritize robotic systems for complex geometries and high speed.

Energy Savings: Opt for insulated ovens and energy recovery units.

Supplier Reputation: Select factories with ISO certification and after-sales support.

6. Safety Precautions for Powder Coating Equipment Package Factory

Install explosion-proof ventilation in powder-handling areas.

Train staff on electrostatic safety and emergency protocols.

Use PPE (respirators, anti-static suits) to prevent inhalation risks.

Ground all equipment to avoid electrostatic discharge.

7. Design Rationale of Powder Coating Equipment Package Factory

Modern factories emphasize modularity, sustainability, and smart manufacturing. Robotic arms reduce labor costs, while IoT sensors monitor real-time efficiency. Stainless steel construction ensures durability, and closed-loop powder recycling minimizes waste.

8. Q&A on Powder Coating Equipment Package Factory

Q1: What is the lifespan of factory equipment?

A: With maintenance, systems last 10–15 years; replace wear parts annually.

Q2: Can factories handle multi-color production?

A: Yes, but require dedicated lines or thorough cleaning between color changes.

Q3: How does automation reduce operational costs?

A: Robotics cut labor costs by 50% and improve coating consistency.

Q4: Are these factories environmentally compliant?

A: Yes, zero-VOC processes and powder recycling meet global standards.

Q5: Is technical training provided by suppliers?

A: Reputable factories offer onsite training for equipment operation and safety.

This guide equips businesses with critical insights into Powder Coating Equipment Package Factories, enabling scalable, efficient, and safe coating solutions for industrial manufacturing.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com